Testing chain friction over time with ProGold

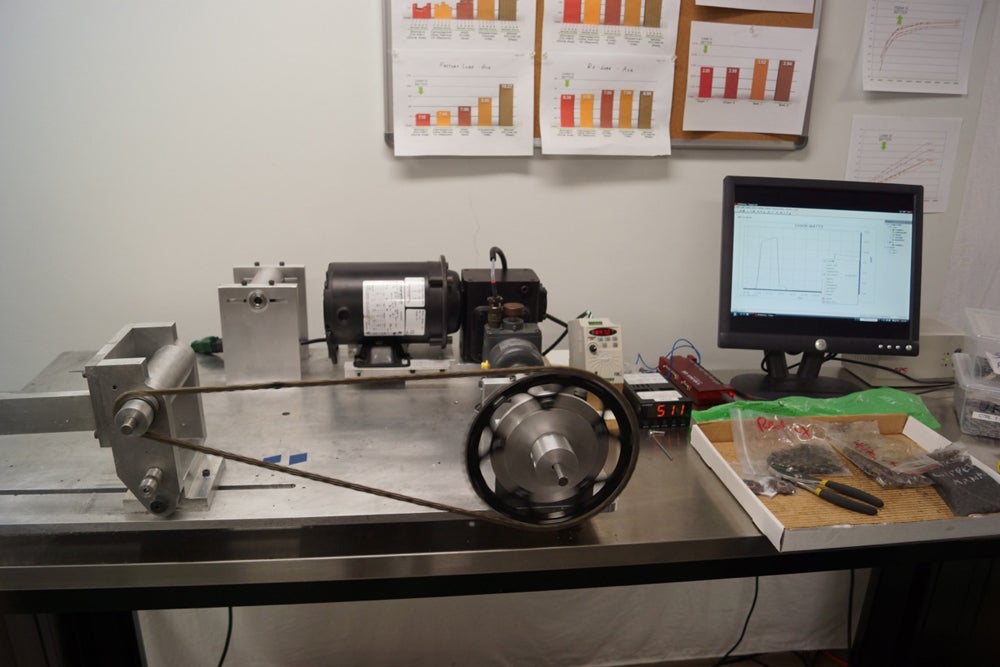

The full-tension chain friction test machine at Friction Facts. (Photo: Lennard Zinn | VeloNews.com)

In a recent Technical FAQ column, a reader asked a question that I have received a number of times regarding regular use of ProGold ProLink chain lubricant: Does using ProGold ProLink regularly reduce chain friction over time by smoothing the contact areas in the chain? To answer this, I turned to Friction Facts, one of our independent VeloLab partners in Boulder, Colorado.

As had happened with this reader, a ProGold employee once explained to me that ProLink is a “metal conditioner” with this effect. He told me that if you were to look at the surface of the metal in a chain with a high-powered microscope, it would look like the profile of the Pyrénées, rather than the smooth surface it looks to have without magnification. He said that, with frequent, regular use, ProLink would, over time, smooth those peaks down so the chain would run with lower friction. The ProGold website currently only says that ProLink “utilizes metal friction reducer technology.”

I believed this “metal conditioner” explanation and have passed it on a number of times, even in my maintenance books. I have used ProLink daily (or nearly that) for probably 10 years now. I still wear out chains, but I believed that it happened with less frequency than before, despite having been religious for at least 20 years about wiping and lubing my chain with some sort of chain lubricant after almost every ride. This past year I was riding more than I have in many years and went through an 11-speed Campagnolo chain much faster than I expected, and I went through two chains in one season on one of my cyclocross bikes last season.

When the VeloLab chain friction test we conducted at Friction Facts appeared in the March 2013 issue of Velo magazine, it showed that ProGold was ranked far from the top in friction reduction on new chains. I, too, thought that perhaps that test, being done on new chains, did not reflect the improvement over time that ProLink is purported to offer. It piqued my interest to test older chains that have been regularly lubricated with ProLink to see if there had been a friction reduction over time. I recently conducted exactly that test with Jason Smith at Friction Facts, and we could see no evidence of friction reduction over time with regular ProLink usage.

Procedure

I brought four used chains to Friction Facts: two SRAM 1091R chains (one from my travel road bike and one from one of my cyclocross bikes), a Wippermann Connex 10sX stainless steel chain that I keep as a spare in my travel bike case, and a KMC X10SL chain from my other cyclocross bike. All of them have been regularly lubed with ProLink over time, and all were still within wear specs (they run on new cogs without skipping under load). None of them had ever been cleaned; I just had done with them what the ProGold employee had suggested, which is simply to wipe them with a rag and lube them frequently with ProLink, starting when new.

We had not tested these particular chains when new, so this was not a before/after test and should be viewed as indicative, but not definitive, of testing the same chain over time. We ran the chains on Friction Facts’ full-tension chain friction test machine; visit Friction Facts’ website for a description of the machine and how it works.

We had results on these same types of chains, in new condition, from the VeloLab friction test and other tests Friction Facts has performed on chains in the past. The frictional drag results in the VeloLab test on the new, clean chains lubricated with ProLink, of which one chain was a SRAM PC1091R, were always below eight watts, and the average was 7.23w. However, our results for the used chains lubricated over time with ProLink were always above eight watts.

This indicates that the chains do not run faster after long wear with regular ProLink application than they do when new and lubricated with ProLink. We did not test cleaning the old chains and then putting ProLink on them, as I was interested in the results for chains maintained over time just as the ProGold employee had told me to do, namely: wipe them with a rag and lube them with ProLink after every few rides, and don’t clean them with solvent.

When we added ProLink to one chain, the KMC, while turning without load on the test fixture, the drag dropped by 0.42w, from 8.58w to 8.16w. When we subsequently lubricated that same chain with the second-best-performing lube in the VeloLab test, the Rock and Roll Absolute Dry, that same chain dropped by almost two more watts, to 6.33w. (In both cases, we just dripped the lube on; we did not do any chain cleaning.) When we applied WD-40 Bike Dry Chain Lubricant on the old Wippermann chain, it did not change the drag at all from its performance with ProLink that was still on there from years ago, as I have been carrying that chain around for a while as a spare.

Results

The graph at the top of the story, Image 3 in the gallery, shows the entire test.

The first peak on the graph is a new, Friction Facts “UltraFast” chain (in this case a 10-speed Dura-Ace), on which Friction Facts performs the following steps:

The UltraFast chain optimization summary: A new chain is run-in under load on the lab equipment. This run-in process polishes the link’s sliding surfaces and removes roughness and manufacturing imperfections. The chains are then ultrasonically cleaned to fully remove the factory lube and friction-producing contaminants introduced during the manufacturing process and run-in period. The chain is then ultrasonically infused at high temperature with a Wax/PTFE/MoS2 blend. The chain is removed from the wax bath, cooled, and run at load again to allow the now-hardened wax blend to further bond under pressure to the metal surfaces and set up the thin lubricating layer between the pins, plate shoulders, and rollers. A second PTFE layer is applied, and finally the chain is placed on the lab equipment for a final run-in and measurement of the friction level. The equipment screen capture is included with the chain. This two-step lubrication process allows the sliding surfaces of an UltraFast Chain to have three distinct lubricating layers working together as a system.

The second peak is a new chain (in this case a SRAM PC1091R), cleaned and lubricated with the worst-performing lubricant in the VeloLab test, White Lightning Epic Ride.

The third peak is my old, ProLinked-over-time SRAM PC1091R chain from one of my cyclocross bikes (used the second half of the 2012-13 cyclocross season).

The fourth peak is my old, ProLinked-over-time KMC X10SL chain from my other cyclocross bike (used the entire 2012-13 cyclocross season).

The fifth peak is to be ignored; it is just the machine running under no load during application of ProLink on that same KMC X10SL chain.

The sixth peak is that same KMC X10SL chain after fresh application of ProLink.

The seventh peak is that same KMC X10SL chain after fresh application of Rock and Roll Absolute Dry lube.

The eighth peak is my old, ProLinked-over-time SRAM PC1091R chain from my travel road bike.

The ninth peak is my old, ProLinked-over-time Wippermann ConneX stainless chain from my travel road bike, which has not been used for a while and is kept in a plastic bag in my travel case as a spare.

The 10th peak is that same Wippermann ConneX chain after application of the new WD-40 Bike Dry Chain Lubricant. This lube was from a sample container handed out at a bike event; it was not tested in the VeloLab chain-friction test, because it was not yet available at the time that test was conducted.

Note that we did not run any new chains with ProLink in this particular test; the comparison I make to them above is based on the VeloLab chain test results. Friction Facts has demonstrated consistency of its results on its equipment over time, so we are confident that we would have gotten the same result as the VeloLab test, had we run a new, cleaned-and-ProLinked chain during this particular test.

Summary

We could find no evidence that frequently wiping down a chain and lubricating it with ProLink will reduce its friction over time in comparison to a new chain of the same type with the factory lubricant cleaned off, followed by lubrication with ProLink.