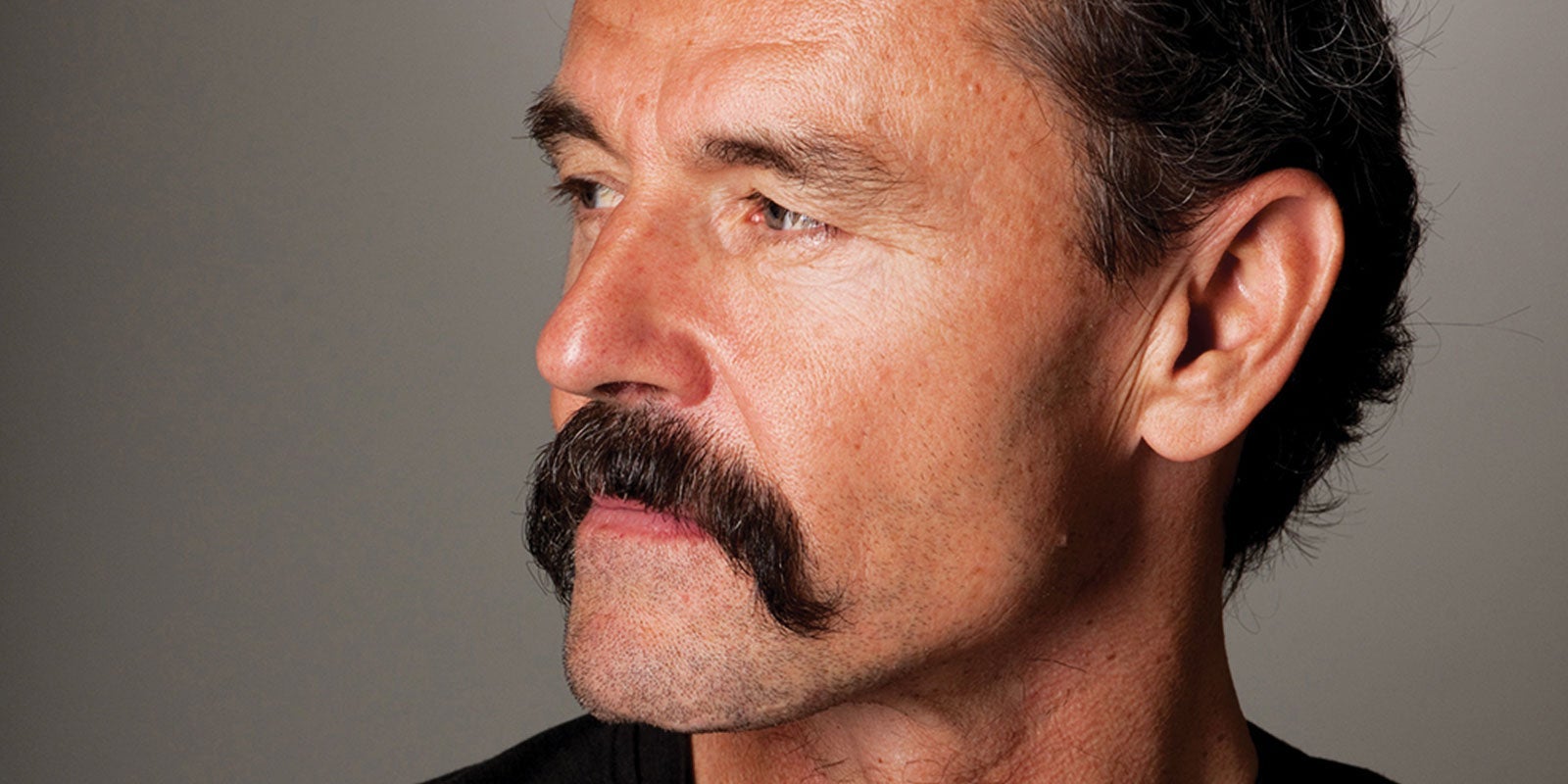

The Pioneer; Tom Ritchey

Tom Ritchey likes to say: “Steel is as old as the sword, the hammer or the spike, but it also goes to the moon.” Ritchey is nothing short of a pioneer in the cycling industry. He built his first bike when he was barely a teenager, reconceived bicycle tubing and was one of the founders of mountain biking. Today, he produces top carbon components, but he never forgets the lessons learned from steel. Ritchey can be outspoken and critical of the industry, but in the end he simply demands that it lives up to the same standards he places on himself.

Words: James Startt

Images: Courtesy, Ritchey

Tom, you are a true pioneer in the sport, especially in steel-frame technology. Take us back to your groundbreaking Logic tubing, the development of TIG welding and your own fillet brazing. What pushed you to rethink the steel tube back in the 1980s, what were you looking to create and what were some of the challenges you faced back in the day? Well, the way that frame building took shape with me was very different from that of a lot of other people that started in the early ’70s. I put my hands on my first set of butted tubing back in 1972. It started with a broken frame that I repaired, a Cinelli that I bought for 50 dollars. I started taking things apart and other people wanted me to repair their bikes, so I started to take others apart. And within a very short amount of time I realized that I could repair bikes. And in the process of repairing bikes I realized that there was a different story underneath the nice paint jobs. And in my youth of 15 years old I thought I could do better.

Having a dad that was an engineer, who was also playing around with materials, played a role too. I actually learned about brazing making an electric car when I was 12 or 13. My dad wouldn’t let me just go out and buy a gas-driven go-kart. In his attempt to slow me down a bit, I guess, he only allowed me to make an electric one. There was a lot of fabricating going on in our house. I was learning in our garage. Since I had a lathe and a mill and other things, I was starting to make things.

In addition, there were two people, my dad and Jobst Brandt, who were very important in terms of safety. My father was simply worried about his son—and then there was Jobst. He was a very important figure on the scene at the time and he didn’t want to lead rides out in the wilderness with somebody bringing something that was going to break. Jobst had been to Europe and ridden some of the great climbs, but he also understood engineering. He was very influential and hard on me in a professionally critical way. As a result, I had this blanket around me that imposed quality control.

Wow, so you were still very much in high school and you were ready to take on the world that was frame building, a very timehonored, old-world tradition? Well, soon enough, it all took on a business sense. When it came to fillet brazing, I would have to say that goes back to 1973 or 1974 actually. It started when I focused on bottom brackets. The bottom-bracket area was uniquely important to me. The bottom bracket was sort of the Achilles heel of the frame, and I had seen a lot of broken ones. It occurred to me that ovalizing the seat tube would strengthen the bottom bracket. And it occurred to me that putting a unique bridge in the back of the chain stay, something people called a “park bench,” would also increase the stiffness of the bottom bracket. And it occurred to me that this heavy and hard-to-find piece of casting, a Cinelli or Masi bottom bracket, was still just a chunk of steel that didn’t have to be so heavy. As a result, I came up with my own bottom bracket with fillet brazing.

My bottom-bracket design became very important in the first mountain bikes, but it actually started on the road. It was a unique problem that I previously solved with the fillet brazing I used in the bottom bracket and I was able to transfer it to other parts of the bike. If the fillet brazing was strong enough for a bottom bracket, it was strong enough for other areas of the bike. Already, in 1974, I had made my first fillet-brazed bike and soon enough I was playing around with different tube-set-diameter thicknesses, et cetera. It led to all kinds of experimenting in tubing. To be honest, some of these things I am sharing with you, I have never shared or explained before. In those early years I soon understood that if I approached fillet brazing in a unique, delicate way, I could use less and less butting. Lug brazing up to this point had often been a sort of blast-furnace approach, but I learned that if I controlled my temperatures, based on external temperature rather than traditional internal temperature, I could use less heat and have a less heat-affected area. It’s interesting looking back, because all of these things came from a 16-or 17-year-old that was trying to make a faster bike for himself.

Looking back, is it fair to say that you were not alone? That there was actually a pocket of racers and builders in California who were really pushing the envelope? Well, when I built my first frame, I built it the way I wanted to build it. I silver brazed it with lugs. I raced it and started to win. I sort of became the local guy that was beating some of the best. That led me to build a better bike, so I built bike No. 2 and No. 3. And other racers, who saw that I was winning, wanted me to build a bike for them. Pretty soon there was a community in California that was buying my bikes. But, yes, there were fellow racers like Peter Johnson, Harvey Nitz and Rory O’Reilly that were doing the same thing. Some of these guys were on the national team and were international racers in the day. As a result there was a real racer-driven, Northern Cal racer / frame builder one-upmanship. It was a lot more than just me building my own racing bike.

To be honest, when I look back, I just have to say that it was such a different time. People had a different relationship with their bikes. The mindset during that era was just different. All of the racers worked on their own bikes. People built their own wheels. People built their own bikes. People understood their bikes. The mechanical aspect of the bike was very much part of the racing experience.

How did your experience building mountain bikes influence or affect your approach to the road bike? Were they very different approaches or was building a road or mountain bike complementary? Well, by 1980, I’d built about a thousand road, track and tandem bikes, mostly building lug-less rather than lugged bikes. By this point, I was pretty much known as the guy that didn’t use lugs, and that gave me a lot of freedom to go wherever I wanted to go in terms of tube diameter, frame geometry…or really anything.

But I’d also built about 50 tandems without lugs and, of course, those frames require a really strong structure. To do it right, tandems required oversized tubes and superstrong forks. There was quite a bit going on in tandems. Strength is No. 1 with tandems and they have been central to a lot of design decisions I’ve made as a frame builder.

Hence the mountain bike was easy for me to segue into. I was building a tandem for Joe Breeze back in 1978 and he told me about this mountain bike that he had built up for the woods, and I was like: “Oh, I think I’ll build something like that too!” On his way home, he ran into Gary Fisher and said that I was going to build a mountain bike. Gary called me and said, “If you are going to build one, can you build me one too?” We had raced together and, since we were the same size, I said yes—and that was pretty much the beginning of the “Mountain Bike” thing and a three-year partnership. [The brand was founded by Gary Fisher and Charlie Kelly, with Ritchey doing much of the building]. It is a story that has been told by others. Charlie Kelly talks about it in his book with Gary. But my story has never been fully told.

Your steel Logic frame has been a fixture of the company for years. How has it evolved? Well, in the 1980s, road racing was still about steel but things were starting to change dramatically because of what mountain biking was bringing into the sport. Big-tire biking with suspension forks and aluminum tubes was very popular. Companies like Cannondale were the real darlings of the industry, with their unique oversized aluminum look. But there was a lot of immaturity when it came to concept and design. A lot of the new people didn’t understand things like Q-factor, ergonomics and the biomechanics of the rider’s position.

Yet there was the economics. Cannondale came out with a frame that probably cost 25 dollars—a frame with big tubes—and it was a huge marketing success. It really took the industry off guard. They took that same frame and used it across the board on probably all of their bikes. All they did was change the components. That had never been done before. You would never take that business approach if you were in the industry for a long time and been using quality steel tubing—to think that you could take the lowest manufacturing process and just hang different parts on it. But Cannondale did that and they had incredible margins. And then the big down tube provided a huge new billboard for the brand. And with industry-wide insecurity, the billboard size of a down tube became the new standard. All of this created the dawning of the aluminum era that was not based on higher quality or design or frame building, but was based on marketing. And of course you could not build an oversize steel tube to compete, because it would be weight prohibitive. As a result, steel was out of business for years.

That said, my answer to the aluminum fad—and I did consider it a fad—was to develop the first P-23, a 23-pound mountain bike that did very well, winning the inaugural 1989 Mammoth World Cup with Don Myrah. Team Ritchey won a lot of races with Henrik Djernis, Thomas Frischknecht and Ruthie Matthes, and as a result a lot of other racers wanted my steel bikes. A lot of racers would actually buy my frames and paint them over. So in the early 1990s, up until I’d say 1996, steel fought back and was very much still in the mix in mountain biking. But it wasn’t easy. I was very involved with my mountain bike team and spent a lot of time in the pits. Unlike a lot of my competitors, I was working and developing material closely with the riders. It took a lot of time and investment on my part, but I wanted the riders to have the best tools to win with and, as a result, I was truly the smallest company able to compete at that highest level. But ultimately steel went bust in the face of dual-suspension aluminum and carbon. I had tons of steel products that never saw the light of day. And for a long time, I never knew if it would come back again or not.

Well, like vinyl records, steel has returned. Like vinyl, it doesn’t hold the same place in the market that it once did. But it definitely has its place in the market, something that was not true 10 years ago…. I was always devoted to steel. I always rode steel myself and preferred it. Aluminum and carbon just didn’t feel right to me. I understood that, if you needed an ultra-stiff bike for the track or a time trial, other materials could be preferable; but for overall functionality steel was hard to be beat. So my relationship with steel never changed.

However, it is sort of like that quote by Ronald Reagan: “I never left the Democratic Party, the Democratic Party left me.” I didn’t leave my roots in steel or the design that the Logic tubing left on the industry. But the industry left steel; they just gave up on it.

And now that steel has come back, there is renewed interest in the Logic tubing. It was so revolutionary and evolutionary, especially when it comes to its TIG-welding applications. With very few modifications, what we were doing back in the 1980s is completely applicable to the bikes we are designing today. Okay, there are some differences, say with sloping top tubes, the integrated head tube and the carbon front forks that are standard today. The whole front of the bike is very different. Those things were not there when the industry left steel. So, mostly, the Logic tubing simply has to be “tuned” to all of those new things that are going on today.

It’s a challenge though. And my challenge is to do it intelligently. A traditional 1-inch fork for example, was softer and more compliant than a 1-1/8-inch. To make carbon safe it has to sacrifice some of its shock absorption to maintain its crash-test strength. Steel in a crash testing yields and bends, but it doesn’t break apart. Carbon fiber will fracture and nobody wants carbon-fiber shards sticking in their body. As a result the industry has had to produce super-stiff forks that have safe crash-test standards. They are not ideal in terms of handling but they are lighter and have become the standards of the day.

How do you see steel bikes evolving in years to come? Well, that’s a great question and one I think about. There’s been a lot of poor understandings. In order for steel to evolve, if it’s to go back to being the way it was, it has to incorporate the state of people’s minds today that have embraced carbon forks and other things. Certain things have devolved and need to be understood, while other things need to evolve and make room for the new things people want to use. But there have been improvements and the value of the pure ride-quality of steel is rebuilding in people’s minds.

It’s a constant balancing act however. The head tube of today’s Logic for example is a forged head tube that incorporates the bearing for a superior ride. A lot of people have machined out a big tube thinking it looks cool. So there is a balancing act between a tube’s big diameter over its strength. It’s frustrating to say this, but there are very few engineers that build today. There are a lot of builders today that are into art and style. Paint jobs can cost more than bike construction these days.

You also make high-end carbon bikes. How has your experience in steel affected your approach to carbon? Well, to start with, there has been a lot of misinformation in the marketplace today and the big companies have risen up and are using whatever marketing effort they can to defend their big tube sections on frames, basically their billboard space. They are going to tell you that it is more elastic, compliant or whatever.

But they have already had to walk backwards. Look at the diameter of the seat posts. Today they’re back to the 27.2 size. In order for a carbon bike to match the weight of a beer can and not to break, it has to be super-stiff. If you have stiff rims and a stiff frame, the only way to gain elasticity is in the seat post. It’s the last place they can find some flex in the system and keep their billboards. They will talk about aerodynamics until the cows come home but, basically, bikes are less rideable to the average person. There is a cost and consequence to the emphasis on weight and aerodynamics.

That is why, when you look at my carbon Break-Away frame, the obvious thing is that there are conventional diameter tubes. That is because the only way that you can get elasticity out of carbon and assure good ride quality is to go back to making it to a more similar diameter to steel tubes. The bending equation in diameter of the tube is the function of the square root of that tube. And the strength of that tube is a torsional-formula cube of that tube. These are all formulas that I learned and understood from my engineering friends back when I was a teenager working with steel. Tubes need to bend, to arch and bow, to absorb shock. Building bikes with more traditional-diameter tubes is the way you get that. So, my choice of tube diameters on my carbon bikes is a very clear reflection of the lessons I learned in my years working with steel.

More at ritcheylogic.com

From issue 69.