Specialized refines Roval Rapide CLX II and Alpinist CLX II as tubeless – details and ride impressions

(Photo: Ben Delaney)

[Editor’s note: The story was corrected. The original story said the Rapide CLX II and Alpinist CLX II were Roval’s first road tubeless wheels.]

After a false start in 2019 followed by two years of investment in R&D, Specialized now has tubeless designs for its new Roval Rapide CLX II and the Roval Alpinist CLX II. The carbon tubeless wheels feature hooked beads, a 110psi maximum inflation rating, and, Specialized claims, an exceptionally strong and resilient design created specifically for the unique dynamics of tubeless setup.

Since 2020, Specialized has been selling and outfitting its teams with the aerodynamic Roval Rapide CLX and the lightweight Roval Alpinist CLX clincher wheels. These new tubeless wheels have identical external shapes to their clincher predecessors: The asymmetrical $2,800 Rapide II pairs a 35mm-wide, 51mm-deep front with a 30mm-wide, 60mm-deep rear for a 1,505g set that handles calmly in gusty winds. The $2,650 Alpinist II is a 1,250g set of 33mm-deep rims. Both sets are 21mm internally.

The original Rapide CLX and Alpinist CLX clincher sets were initially slated to be sold and raced as tubeless — until Peter Sagan broke one in testing in 2019.

“With Sagan and all of our riders, even the prototypes that they are riding have always been tested to pass the UCI standards and our existing standards,” Specialized global marketing leader Ben Edwards told VeloNews. “By this point, Quick-Step had also been testing the Rapide and Alpinist, and wanted to use those wheels, so they raced them as clinchers for two seasons.”

Meanwhile, Specialized went back to the drawing board to further quantify loads a tubeless wheel could encounter, then build tests for those loads, and rework the two wheelsets’ layups to handle those loads.

“We don’t think the existing wheel-testing standards are ideal for tubeless wheels,” Edwards said. “For one thing, the UCI test uses a rubber striker directly on a wheel, without a tire. It’s not really challenging the entire system. And we know that a tube-type failure is different than a tubeless failure.”

“With a clincher, even an abrupt puncture allows air to escape over a second longer than with a tubeless system, where if get a crack in that pressurized vessel, there is a lot of force almost immediately acting on that point,” Edwards said. “So, we built and tested to a much higher level.”

Joules, the UCI, and real-world testing

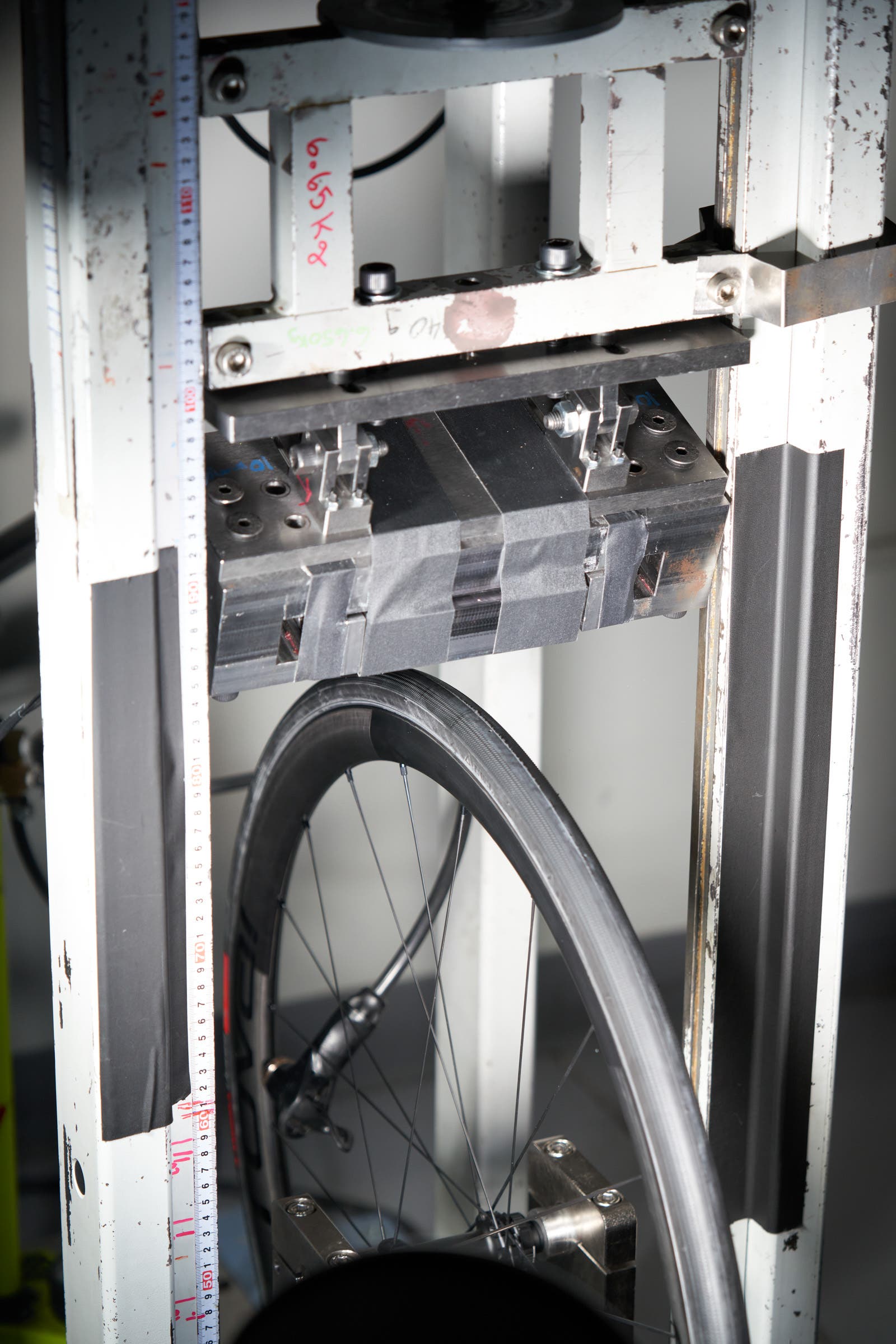

The UCI’s wheel safety test involves a dropper a striker at 40 Joules. What’s a Joule, and how does that translate to riding a bike, you ask? Many inside Specialized had the same question, so they measured the force of a rider hitting a big bump at speed.

A 180-pound rider hitting a two-inch square-edge bump at 20mph generated 29 joules, Specialized found. From there, Specialized engineers ramped up testing to 40, 50, 55, 60, and 70 joules. The latter impact would involve massive crashes where a rider even hanging onto the handlebars would be unlikely, Specialized said, but they wanted the wheels to remain intact enough — and the tire to remain on the rim — in order for a rider to roll to a stop safely… should they still be on the bike.

To get the wheels to meet those standards involved trying 150 different layup iterations and making more than 1,000 wheels.

The Alpinist II ended up at the same weight. The Rapide II ended up being 100g heavier.

“That weight came from completely understanding the failure mode at a very high force, and being built to withstand that,” Edwards said.

Why a hooked rim instead of hookless?

Clincher wheels and tires, by definition, lock into each other with a tire bead ‘clinching’ onto the hooked rim of a wheel. Many tubeless tires and wheels operate similarly, but some newer tubeless wheels now have hookless rims. The arguments for hookless include a stronger, simpler design, and a better interface for tire shaping. So long as both the wheel and the tire meet agreed-upon standards (the ETRTO specifications), then safety is ensured, hookless proponents argue.

Specialized, and others who make hooked tubeless rims, argue for the continued value of the small lip around the edge to help keep the tire on the wheel. Specialized makes hookless mountain bike rims.

“When you go hookless for road wheels, and you are telling riders they have a 75psi maximum, and they must use a 28mm tire, we feel that is not the ideal scenario,” Edwards said. “We believe in tubeless, but not in the handicapped version of hookless tubeless.”

As such, the new Rapide CLX II and Alpinist CLX II tubeless wheels can be used with pressures up to 110psi, should riders want to go that high.

Stable design for unstable humans

As with the Alpinist, the Roval Rapide external shape was settled on when the tubeless project began anew. Unlike the Alpinist that was designed entirely for ride quality including light weight, the Rapide was built for speed and stability in sketchy winds.

The dual-depth design isn’t new — Enve has done the shorter-and-wider front with taller-and-narrower rear since 2011 — but it is an effective one. Within reason, the taller the rim, the faster the wheel is, and the more challenging it is to handle in crosswinds, particularly gusty ones. So, the Rapide’s front rim is still tall at 51mm but shorter than the rear, and substantially wider to reduce crosswind turbulence.

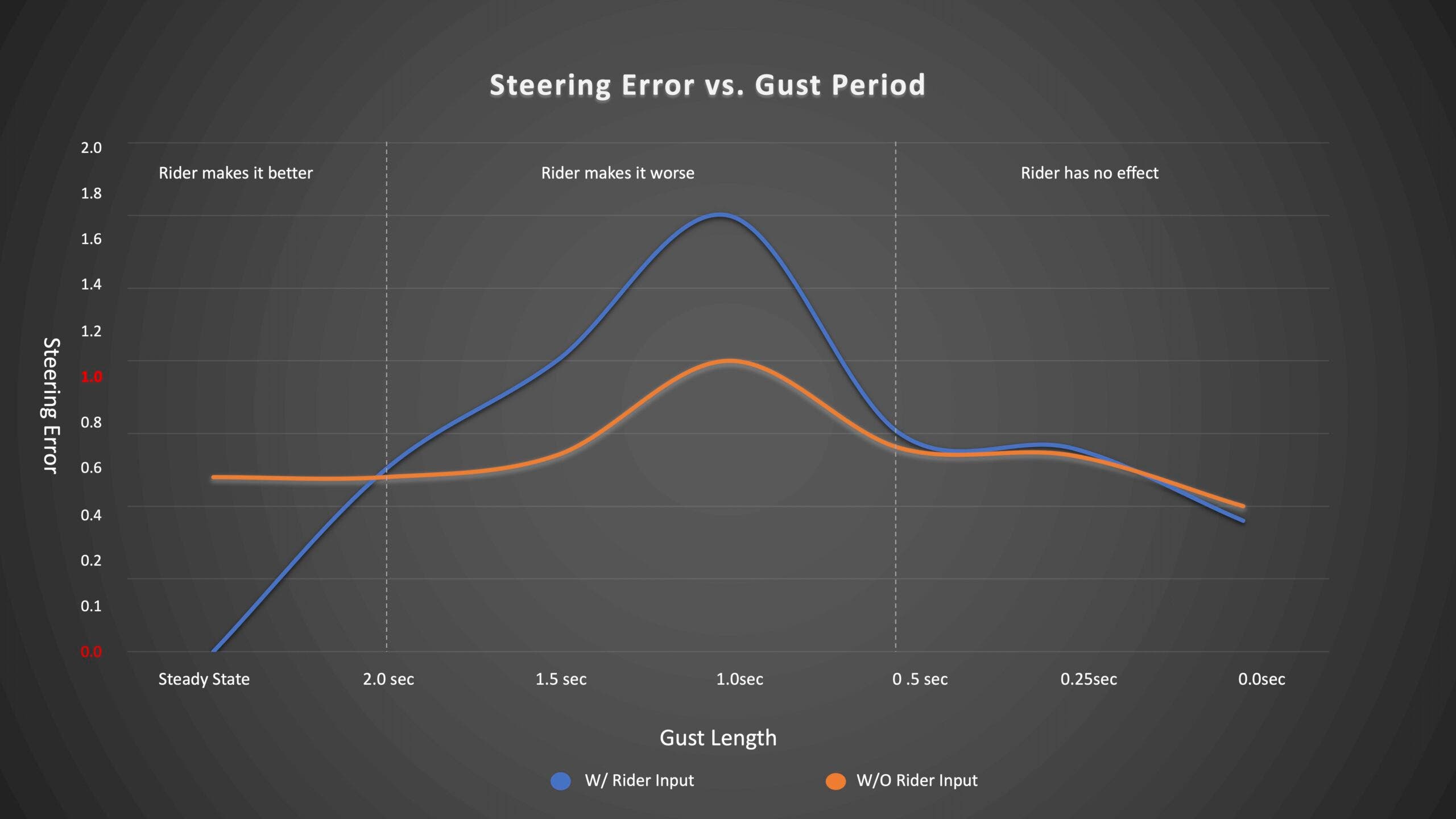

Specialized designed the Rapide, particularly the front, to optimize stability for wind gusts in the half-second to two-second window. Shorter bursts of wind are too quick for a rider to react to, and longer crosswind gusts are steady enough that a rider can adapt. But that half- to two-second window is where riders can actually make things worse by overreacting, Specialized engineers found.

“That rider-reaction window, that’s not something we had to invent ourselves. It came from aeronautical studies — how do you handle a plane in heavy wind — and automobile studies. They found that reaction time is really consistent. It’s that half-second to two-second window where you can get yourself into trouble,” Edwards said.

Roval Rapide CLX II ride impressions

I tested a set of the Roval Rapide CLX II on the heels of riding a few other models of similar depth, including Shimano’s new Dura-Ace C50 and Enve’s 4.5 AR wheels.

Testing wheels by feel is a funny thing, because there are obviously so many other factors that influence the feel, from the tires and air pressure to the rest of the bike to wind conditions and then all the other human aspects. As the chart above shows, sometimes it’s the human on board that can hamper performance.

In any event, the Rapide CLX IIs feel fast, relatively light, and very calm. I live in Colorado, where the wind is my least favorite thing about the state. I often use the Epic Ride Weather app to map the forecast of a given route, with the wind speed and direction being the critical point of interest. Point is, wind is a thing, here.

The most notable thing on the Rapides is the massively wide front rim. At 35mm wide, the rim protrudes way out past the 26mm Specialized Turbo tires I was using. I have the same tires on the Shimano C50s, which are 28mm wide front and rear. Descending mountain canyons, the Colorado spring wind will often slap you as you come around a bend, or past a rock formation. It’s not a great feeling. On the Rapides, however, the pressure on the front wheel felt more like a steady push and not a violent shake.

While the Shimanos have a hooked bead for their 21mm internal-width rims, and the Enve wheels I had been riding are hookless, and came with a 80psi maximum pressure rating. If you want to run higher pressures, that is certainly something worth noting.

I used the wheels for a long birthday ride where I topped 50mph a few times with crosswinds, clawed into headwinds, and then sailed home with a tailwind and cross-tailwind. On a blustery day riding mostly alone, the Roval Rapide CLX II set was a fun, steady companion in the wind.

I would happily ride or race this set any day, and the two-year, no-fault crash replacement policy is potentially as valuable as any particular performance characteristic.