VN Awards: Cycling brands get greener

(Photo: Courtesy Giordana)

The 2021 VeloNews Awards are running all the rest of the month for VeloNews and Outside+ members.

Lip service to eco-friendly practices is easy, but structural change? Not so much. Businesses operate on black and red (what is profitable and what is not), not on green (what is healthy for the planet and us as people on it). Further, even though green practices are trendy to speak about these days, some businesses are wary of being called out for “greenwashing,” the practice of marketing environmentally friendly practices in the hopes of getting sales without actually making substantial changes.

Yet a healthy environment is of utmost importance. As cyclists, we know this. Beyond the large-scale implications of climate change, we have a very tangible appreciation for a clean environment. None of our riding dreams include breathing dirty air while pedaling through a poisoned, littered landscape. Similarly, on the manufacturing end of the bike world, none of us want to work in a place that is generating harm.

So this year, we salute the companies that are making positive environmental changes that benefit all of us. As with individuals, none of these companies is perfect; but here are three examples of companies headed in the right direction.

Clothing bags that can go into the garden

Giordana has been producing cycling apparel in Italy for decades. In recent years, the company opened its own factory, allowing it to control every step of the production process.

“The European Union’s standards are higher than other countries and we have upheld these for many years already. Our production exceeds the EU’s requirements for green practices,” said Giordana’s Jenny Tuttle Rollyson. “We use gentler, water-based inks. Excess fabric cuttings and printing paper are recycled. Skylights provide natural light to reduce electric consumption.”

Beyond how the product is made, Giordana has invested in reworking its packaging. Rollyson said 95 percent of the company’s packaging has been redesigned specifically to improve sustainability.

Perhaps the most important change was in the bags. Giordana and virtually every clothing company ships jerseys, bibs, jackets, and more in bags. Traditionally, these bags were plastic. Now Giordana uses a biodegradable and compostable material for the bags. Instead of going into a landfill, the bags can go in the garden, or at least in the compost container.

“We looked at every component of our packaging and collateral — from printed materials to retail display, to shipping, and made moves to lessen our environmental impact,” Rollyson said. “We’ve reduced the thickness of paper, moved to recycled materials and cardboard with post-consumer waste, and sourced new eco-friendly suppliers both in the U.S. and Italy to align with our company values.”

Measure, improve, and measure again

At Trek, various internal groups had been making improvements to their own environmental practices, but a dictate from the top galvanized the company. For Trek president John Burke, the movie Above and Beyond proved pivotal. The documentary begins with the intent of documenting the United States’ push to put a man on the moon with NASA, but pivots to a dire call for environmental action, as NASA has so much data on the earth and the rapidly changing environment.

The movie scared Burke. He insisted that others in the company watch it, and then pushed Trek to talk about specifically what it could do.

“Two years ago, [Burke] was like, ‘We are going to become a green company, fast. Find out what that means for your business unit, and march.’ That sent people in a lot of different directions. And we had varying degrees of success,” said Erik Bjorling, who spearheaded Trek’s mission to objectively measure itself in order to improve.

“We have a lot of corporations coming out with statements on things like being carbon neutral,” Bjorling said. “We decided, let’s find out where we are now, and make sure whatever we do is meaningful.”

So, Trek had a third party measure its impact for a year, with two main studies in manufacturing and operations. The study followed four types of bikes through the manufacturing and shipping processes and extrapolated from there. For instance, the Trek Marlin was chosen to represent hardtail mountain bikes and hybrids, and a Madone was picked to represent the impact of carbon road bikes.

The study was completed this year, and Trek published the report in July.

“We found our operation number really pales in comparison to manufacturing,” Bjorling said. “We thought keeping the lights on would be a big thing, but it’s really miniscule compared to transporting product across the world. It was a really eye-opening exercise for us.”

From there, Trek set out to determine what change could be affected. And Bjorling said at this point it was crucial to have executive buy-in. For instance, shipping a bike on a plane has 84 times the carbon impact of shipping it on a boat, but obviously, a plane is faster.

“We were all startled by the impact of air transportation, but it took John saying, ‘Is shipping by air really this much? Then we are going to drastically reduce the air freight that we are going to rely on.”

At Burke’s instruction, Trek committed to reducing air freight by 75 percent of pre-COVID-19 levels by 2024.

Similarly, after getting a clear picture of what the biggest impacts were, Trek laid out other measurable goals for improvement. In its report, Trek lays out 10 areas for improvement. Many of these have specific targets, such as doubling the use of recycled materials in products by 2022, using 100 percent renewable energy for all facilities by 2023, and creating zero-landfill manufacturing facilities by 2024.

A number of Trek and Bontrager parts that used to be plastic (such as bottle cages, grips, and Garmin mounts) are now made from recycled or non-plastic materials. For 2021, Trek claims it was able to remove more than 100,000 pounds of plastic packing just by reducing the number of plastic shipping pieces on its most popular bike, the Marlin. Starting in May of 2020, Trek reduced the number of non-recyclable pieces used to ship the Marlin from 24 to 12.

“Our packaging team has done such a great job,” Bjorling said. “The goal is to remove as much plastic as possible until there is no plastic at all. We are getting closer. Some pieces are really hard to replace. We will have six pieces for the Marlin next year. Those last few pieces are hard. But we want to be plastic-free by 2024.”

Bjorling said that while bike companies remain fiercely competitive with one another on product, going green should be a collaborative effort.

“The industry should really be cheering for each other here,” he said. “If we can share knowledge on how to improve, we are 100 percent happy to do so.”

“Buy better, not more”

At the apparel company Velocio, the team is all too aware of the environmental impact of clothing. Marketing manager Zach Levy can rattle off sobering statistics on the apparel industry at large: “Eighty percent of all clothing ends up in a landfill or is incinerated within three years,” Levy said. “And 551,155 tons of plastic microfibers are estimated to pollute the ocean each year from washing clothes, which is equivalent to the plastic pollution of more than 50 billion bottles.”

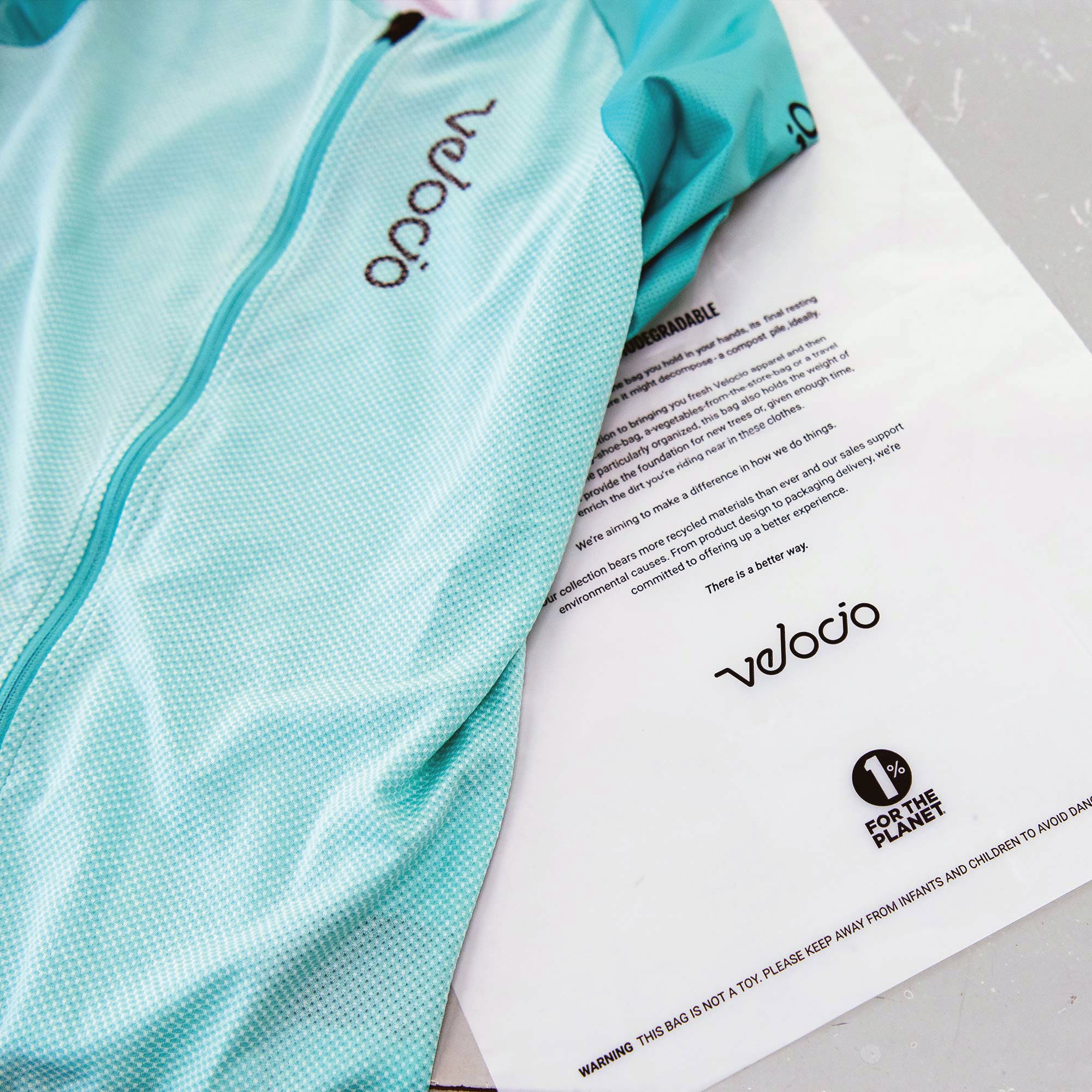

With that in mind, Velocio is working on improving its raw materials, packaging, shipping, energy sources, and recycling and repair.

All of Velocio’s spring/summer jerseys are now made completely from recycled or natural fibers. In North America and in Europe, Velocio offers free repairs to customers, with the idea of extending the life of each garment and thereby reducing waste.

Velocio cuts down on energy consumption by using solar energy at its facilities, shipping by sea and truck instead of air “whenever possible,” Levy said. “As a small brand, we’re pushing back on the ‘get it now’ mentality that demands higher transportation waste.”

And, like at Giordana, Velocio now ships clothing in compostable bags.

“Our packaging is biodegradable, our mailers are compostable, and our fulfillment team uses the least amount of packaging possible when packing orders,” Levy said. “We are asking consumers to demand and buy high-quality products that last, and ways of recycling and repurposing what we do use. We need apparel, but we don’t need to produce apparel the way that we do.”